Unlocking the Potential of PA12: A Comprehensive Discussion on Production and Implementation

Introduction

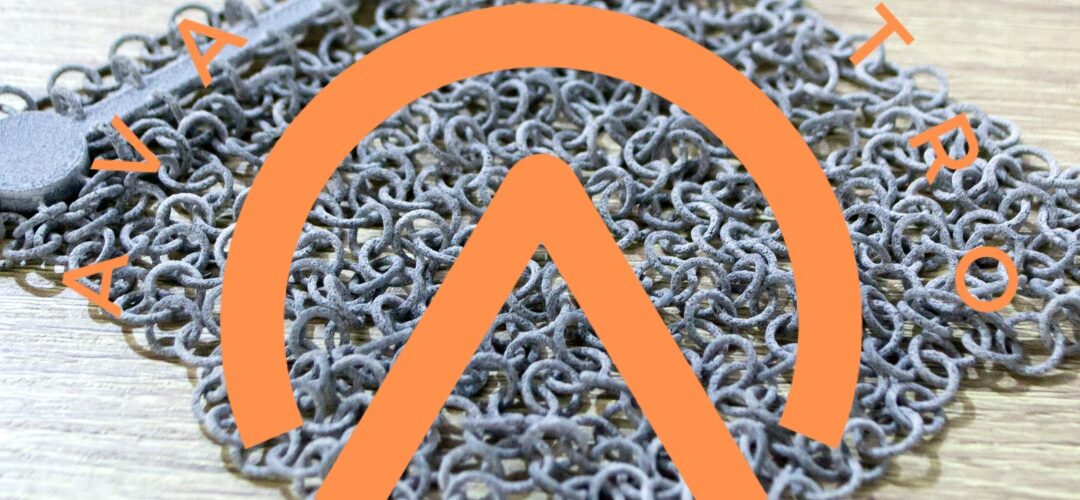

In the realm of cutting-edge materials, Polyamide 12 (PA12) stands out as a versatile and high-performance polymer that has found its application across various industries. In this article, we delve into the intricate details of the production and implementation of PA12, aiming to provide a comprehensive guide for businesses and enthusiasts alike.

Understanding the Basics

What is PA12?

Polyamide 12, commonly known as nylon 12, is a thermoplastic polymer characterized by its exceptional mechanical properties and resistance to abrasion. It is widely utilized in engineering applications due to its high tensile strength and durability.

Production Process

The production of PA12 involves a meticulous process that combines chemistry and engineering. The primary raw material, dodecanedioic acid, undergoes polymerization with dodecylamine to form the polymer chain. This process results in a high-quality PA12 resin, ready for further processing into various forms such as pellets or powder.

Applications Across Industries

PA12’s versatility extends to multiple industries, making it a material of choice for various applications.

Automotive Industry

In the automotive sector, PA12 is widely used for manufacturing fuel lines, brake components, and cable sheathing due to its excellent resistance to chemicals and heat.

Medical Devices

The biocompatibility and sterilization capabilities of PA12 make it an ideal choice for medical devices such as catheters and implants.

Consumer Goods

From sports equipment to everyday items like toothbrushes, PA12’s impact resistance and lightweight nature contribute to its prevalence in the production of consumer goods.

Advantages of PA12 Over Other Materials

Exceptional Strength and Durability

PA12 outshines other polymers with its remarkable tensile strength, ensuring longevity and reliability in various applications.

Chemical Resistance

The inherent resistance of PA12 to chemicals makes it a preferred material in industries where exposure to corrosive substances is common.

Wide Temperature Range

The ability of PA12 to withstand a broad temperature range, from extreme cold to high heat, enhances its applicability across diverse environments.

Challenges and Solutions in Implementing PA12

Cost Considerations

While PA12 offers unparalleled performance, cost considerations may arise. However, the long-term durability and reduced maintenance costs often outweigh the initial investment.

Processing Challenges

The high melting point of PA12 can pose challenges during processing. Employing advanced machinery and precise temperature control can overcome these hurdles.

Future Trends and Innovations

As technology evolves, so does the application of PA12. Ongoing research explores ways to enhance its properties, opening doors to new possibilities in industries such as aerospace, electronics, and more.

Conclusion

In conclusion, the production and implementation of PA12 represent a pivotal aspect of modern material science. Its versatility, coupled with unmatched strength and durability, makes it a go-to choice across various sectors. As industries continue to seek advanced materials for their applications, PA12 remains at the forefront of innovation.

Written by Emir Narin